Keywords: Access Road in OHTL, OHTL access road construction, subgrade CBR requirements, SEC standard TES-P-122.11, sub-base layer, surface course, civil works for transmission lines, access road layers, road compaction standards

What is an Access Road in OHTL Projects?

An Access Road in Overhead Transmission Line (OHTL) projects is a specially designed route that enables the transportation of equipment, towers, and construction teams to tower locations — often through remote, sandy, or rocky terrain.

These roads are vital for construction, inspection, and long-term maintenance, making their design and durability a top priority for transmission utilities, such as National Grid Saudi Arabia (NGSA).

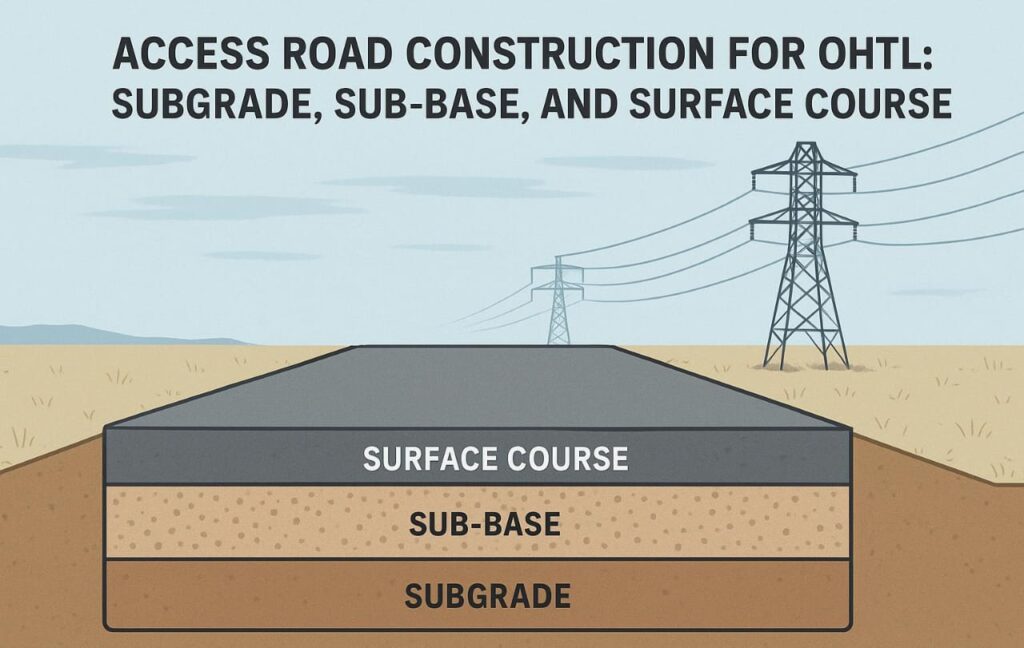

Typical Cross-section of an OHTL Access Road

As per SEC Standard TES-P-122.11 REV 01, a standard OHTL access road consists of the following layers:

- Subgrade

- Sub-base

- Surface/Base Course

Each layer has specific engineering and performance requirements to withstand different soil conditions, traffic loads, and environmental challenges.

Subgrade – The Earthwork Foundation

The subgrade is the prepared ground layer on which all other road layers are placed. According to TCS-Q-113.02, the following requirements apply:

Key Specifications:

- Topsoil removal: Minimum 200 mm of topsoil must be stripped and disposed of at approved dumping grounds.

- Compaction Depth: Subgrade must be scarified and compacted to a depth of 200 mm.

- Minimum CBR Requirement: After 4 days of soaking, the CBR value must be ≥ 15 (ASTM D1883).

- Depressions & Voids: Any unsuitable material must be removed and filled with approved fill materials.

- Alignment & Finish: The subgrade must conform to the designed alignment, slope, and grade.

Note: In areas with naturally low CBR (<15), soil improvement techniques are required to meet the minimum standard.

Sub-base – Intermediate Load Distribution Layer

The sub-base supports the surface course and protects the subgrade from traffic and water infiltration.

Key Specifications:

- Material Standard: Must comply with Class C of TCS-Q-113.02, clean and free from organic matter.

- Minimum CBR Value: ≥ 50

- Layer Thickness: Not to exceed 150 mm after compaction.

- Elevation for Special Areas:

- In sabkha, swamp, or flood zones: sub-base must be raised ≥ 1.5 m.

- In desert/sand dune areas: elevation must be ≥ 750 mm from natural ground level to avoid sand drift issues.

- Compaction: Per Light Traffic road specifications (TCS-Q-113.02).

Surface/Base Course – Final Road Surface

This layer serves as the driving surface for heavy construction vehicles and long-term maintenance access.

📌 Material Requirements:

- Must meet Class B of TCS-Q-113.02 standards.

- Free from debris, organic matter, and boulders.

- Minimum CBR Value: ≥ 75

Construction Guidelines:

- Total Thickness: 300 mm compacted.

- To be laid in ≤150 mm thick layers using approved spreaders.

- Compaction Standards: For Heavy Traffic roads with controlled moisture content (optimum ±1.5% as per ASTM D1557).

- Finish Tolerance: Deviation ≤ 20 mm using a 3 m straightedge.

- No addition of thin layers to adjust grade — final surface must be built to level.

Special Cases – Hilly & Rocky Terrain

In continuous rocky or hilly regions, where bedrock is encountered:

- Access roads may be prepared through rough grading of natural terrain.

- Followed by light compaction, suitable for 4WD vehicles.

- These roads are typically temporary for construction but may be reused for O&M by NGSA upon approval.

Material and Environmental Constraints

- Water used for compaction must not contain more chloride or sulfate than the surrounding soil.

- Seawater is strictly prohibited for any construction purpose.

Summary Table – Access Road Earthwork Requirements (As per SEC Standard)

| Layer | Minimum CBR | Max Layer Thickness (Compacted) | Special Notes |

|---|---|---|---|

| Subgrade | 15 | 200 mm | Improve soil if CBR < 15 |

| Sub-base | 50 | 150 mm | Raise ≥1.5 m in sabkha/swamp areas |

| Surface Course | 75 | 150 mm (per layer) | Total thickness = 300 mm |

Conclusion

Designing and constructing access roads for OHTL projects demands adherence to strict civil engineering standards to ensure long-term performance, safety, and access reliability.

By understanding and implementing the correct procedures for subgrade preparation, sub-base compaction, and surface course finishing — based on SEC’s TES-P-122.11 Rev 01 and TCS-Q-113.02 — contractors and engineers can deliver roads that withstand heavy loads, harsh terrain, and shifting sands common in Saudi Arabia and similar regions.

Proper access roads are not just roads – they are lifelines for transmission infrastructure.