Introduction

In modern high-voltage transmission systems, communication and protection are equally critical. OPGW (Optical Fiber Ground Wire) is the smart solution that achieves both.

It replaces conventional ground wires by integrating optical fibers for communication inside a mechanically strong metallic conductor that provides lightning protection.

What is OPGW (Optical Fiber Ground Wire)?

OPGW is a composite cable installed at the top of transmission towers.

It serves a dual function:

- Electrical Protection — It shields power conductors from lightning strikes and provides a path for fault currents to ground.

- Data Transmission — It carries optical fibers that enable high-speed data communication between substations and control centers.

This makes OPGW an essential component of smart grids and modern power utility communication networks.

Brief History and Development of OPGW

The concept of combining optical fiber and ground wire originated in the late 1970s and early 1980s, when utilities began experimenting with optical communication along power lines.

Early designs used steel tubes wrapped with aluminum wires, allowing fibers to be safely embedded without exposure to electrical stress.

By the 1990s, utilities worldwide—including Saudi National Grid, National Grid UK, and US utilities under IEEE 1138—had standardized OPGW installation techniques.

Today, OPGW cables are common in EHV and HVDC systems, forming the communication backbone for SCADA, protection relays, and remote control applications.

Why OPGW is Used in Transmission Lines

Traditional Overhead Ground Wires (OHGW) only provided lightning shielding.

However, with the growth of real-time grid monitoring and smart substations, utilities needed a medium capable of data transfer as well.

Thus, OPGW became the ideal solution, offering:

- Lightning shielding and grounding path

- High-capacity data channels (up to 96 fibers)

- Reduced cost and tower loading (one cable for two functions)

- Improved reliability and lower maintenance

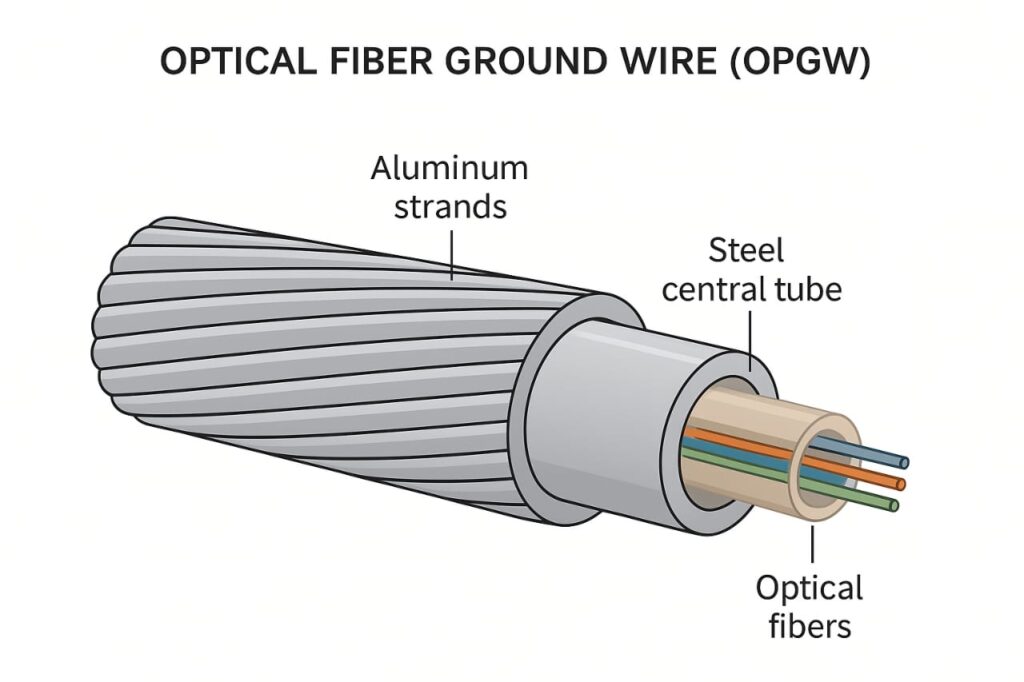

Construction of OPGW Cable

An OPGW cable typically includes:

- Aluminum Alloy or Steel Strands: Provide mechanical strength and conduct fault current.

- Central Tube(s): Contain the optical fibers, protected inside stainless steel or aluminum tubes.

- Optical Fibers: Transmit data using light pulses; often 12–96 fibers.

- Outer Layers: Ensure tensile strength and protect against environmental conditions.

These components allow OPGW to withstand mechanical loads, wind pressure, and fault currents while maintaining low optical attenuation.

How OPGW Works – The Principle

When installed at the top of transmission towers:

- The outer metal layers intercept lightning strikes, diverting current safely to ground.

- The inner optical fibers remain unaffected, transmitting data through light signals.

This structure enables simultaneous electrical protection and optical communication, making OPGW both a safety component and a digital data pathway.

It supports communication for:

- SCADA systems

- Line differential protection

- Teleprotection and fault detection

- Substation automation and data networks

Advantages of OPGW over Traditional Ground Wires

| Feature | Traditional Ground Wire (OHGW) | OPGW |

|---|---|---|

| Lightning Protection | ✔️ | ✔️ |

| Data Communication | ❌ | ✔️ |

| Space Requirement | Separate fiber cable needed | One combined cable |

| Maintenance | Moderate | Lower |

| Network Reliability | Limited | High |

| Life Expectancy | ~20 years | 30–40 years |

By integrating two systems—protection and communication—OPGW reduces project costs and simplifies tower design.

Installation Considerations (Based on TCS-P-122.08-R1)

According to National Grid Saudi Arabia Standard TCS-P-122.08-R1, successful OPGW installation requires strict control of tension, grounding, and communication between teams.

Key points include:

- Maintain a minimum bend radius of ≥40× the cable diameter.

- Use the tension stringing method instead of the slack method for long spans.

- Keep pulling speed between 2–5 km/h.

- Ensure temporary grounding during installation at puller and tensioner ends.

- Test the fibers before and after installation with an OTDR (Optical Time Domain Reflectometer).

These steps prevent fiber damage and ensure both mechanical safety and optical performance.

Challenges and Precautions

- Over-Tensioning: Can damage the metal tubes or fiber cores.

- Sharp Bends: Reduce fiber performance; follow the minimum radius rule.

- Improper Grounding: Can cause dangerous potential differences during stringing.

- Splicing Conditions: Splicing should be done in a controlled environment to maintain low attenuation.

- Environmental Exposure: Sand, humidity, and salt require corrosion-resistant materials in desert or coastal areas.

Common OPGW Standards and Guidelines Worldwide

Several international and regional standards define OPGW materials, design, and installation practices:

| Standard / Code | Region / Organization | Focus Area |

|---|---|---|

| IEEE 1138 | USA | Design, testing, and installation of OPGW |

| IEC 60794-4-10 | International | Optical fiber cables for outdoor power applications |

| CIGRÉ TB 338 | Europe | OPGW reliability and aging performance |

| TCS-P-122.08-R1 | Saudi Arabia (National Grid) | Field installation methods and safety procedures |

Following these standards ensures safe and consistent OPGW installation across projects worldwide.

Applications of OPGW in Power Systems

- 132–500 kV Transmission Lines

- HVDC and EHV Substations

- Utility Fiber Networks for SCADA and Protection

- Smart Grid Communication Links

- Inter-Utility and Telecom Data Leasing

Future of OPGW in Smart Grids

With the expansion of digital substations and IoT-based asset monitoring, OPGW forms the communication backbone of future grids.

Utilities are increasingly using OPGW fibers for:

- Wide-Area Monitoring Systems (WAMS)

- PMU (Phasor Measurement Unit) networks

- Cyber-secure communication between substations

Its role is set to grow as utilities integrate renewable power, AI-based diagnostics, and automation systems.

Conclusion

OPGW (Optical Fiber Ground Wire) is more than a protective wire — it’s a critical enabler of digital power networks.

By combining lightning shielding, fault current conduction, and optical communication, it supports the evolution toward smart, reliable, and efficient transmission systems.

From Saudi Arabia’s TCS-P-122.08-R1 to global standards like IEEE 1138, OPGW continues to define the future of overhead line communication and grid automation.

MORE ON HERE