Introduction

Overhead Transmission Line (OHTL) foundations are critical components in the electrical power transmission infrastructure. They support transmission towers and transfer loads to the ground. Due to exposure to harsh environmental conditions, such as moisture, chlorides, sulfates, and aggressive soils, the Saudi Electricity Company (SEC) mandates robust protective coating systems to ensure durability and corrosion resistance.

This section provides a complete professional overview of the protective coating requirements as per SEC standards, aligned with best engineering practices.

Purpose of Protective Coating

Prevent corrosion of concrete and steel components.

Ensure long-term structural reliability of transmission foundations.

Extend the service life and minimize maintenance costs.

Applicable SEC Standards

1. TMS-11-10 – Protective Coating for Transmission Line Structures.

2. DMS-04-0001 – Protective Coating for Steel Structures and Foundations.

3. CCS-04-0001 – Concrete Works for OHTL Foundations.

4. SEC-NES-P-103 – Hot-Dip Galvanizing and Touch-Up Requirements.

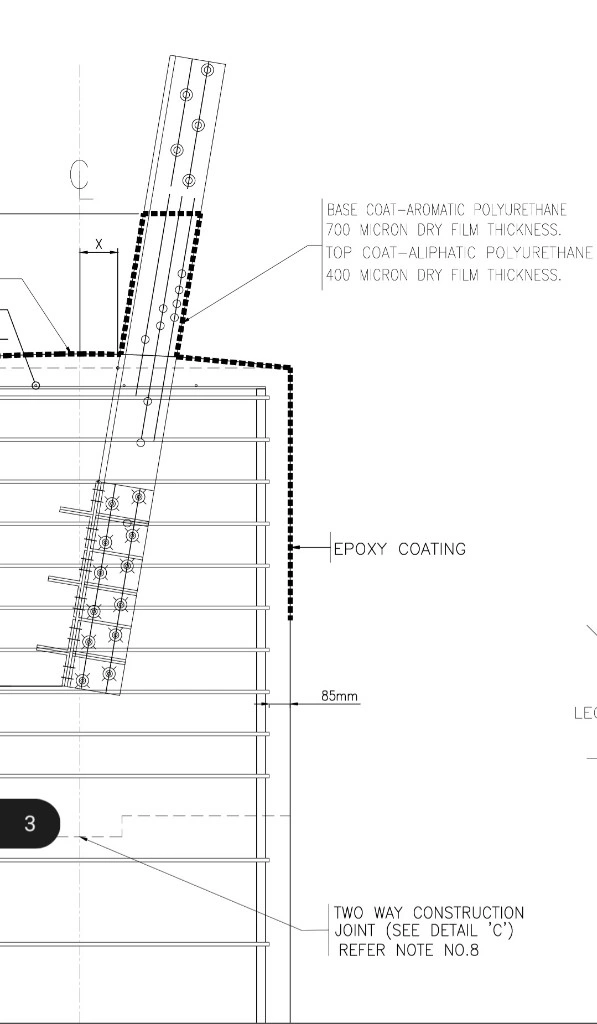

Coating Systems

Component Coating Type Minimum Dry Film Thickness Application Zone

Concrete above ground Bituminous or epoxy waterproof coating ≥ 200 microns Up to 300 mm above final ground level

Steel below ground Coal Tar Epoxy ≥ 300 microns Underground corrosion zone

Steel above ground Zinc-rich epoxy + Polyurethane ≥ 250 microns Exposed atmospheric conditions

Galvanized steel parts Hot-dip galvanizing ≥ 85 microns Long-term cathodic protection

ALSO READ: PLS-CADD for Beginners: Complete Introduction to Overhead Line Design Software

Application Requirements

Surface must be clean, dry, and free from contaminants.

Metal surfaces shall be prepared by blasting to SSPC-SP10 / NACE No.2.

Coating must be applied in controlled environmental conditions (minimum 3°C above dew point).

Inspection and Testing

Visual Inspection for defects and uniform coverage.

Dry Film Thickness (DFT) measurement using calibrated gauges.

Holiday Testing to detect pinholes.

Complete documentation is mandatory as per SEC QA/QC requirements.

Conclusion

Protective coating is a mandatory engineering requirement in all OHTL foundation projects by SEC. Proper implementation ensures long-term reliability, safety, and protection against corrosion. Adherence to SEC standards is essential for compliance, sustainability, and operational excellence.