Overhead transmission lines form the backbone of modern power systems, carrying electricity from generating stations to cities, industries, and rural areas. In regions like Saudi Arabia and the Middle East, the design of these lines must take into account unique challenges such as desert climates, coastal corrosion, strong winds, and lightning activity.

This article explains the essential design requirements of overhead transmission lines, in simple terms, while covering technical considerations that ensure safety, efficiency, and long-term reliability.

1. System Parameters

Electric power systems in Saudi Arabia and most Middle Eastern countries are based on:

- Frequency: Standard is 60 Hz. A stable frequency ensures that equipment like motors and generators run efficiently.

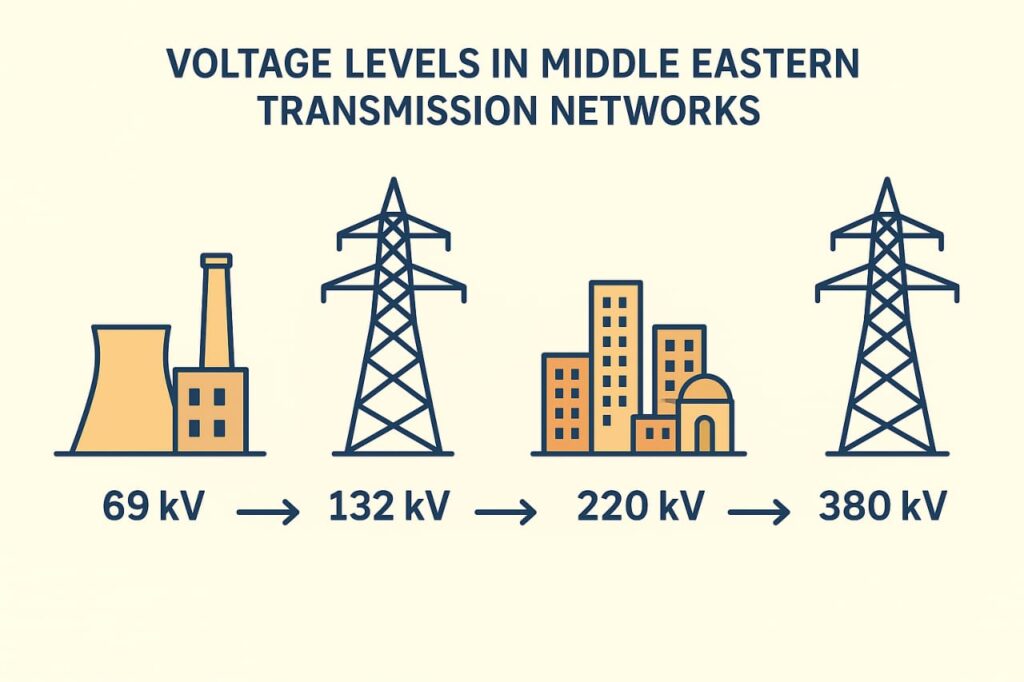

- Voltage Levels: Common transmission voltages include 69 kV, 115 kV, 132 kV, 230 kV, and 380 kV. These levels are chosen based on distance, power demand, and economic feasibility.

- Operating Tolerance: Transmission lines are designed to handle about ±5% variation in voltage. This ensures reliability during peak loads or emergencies.

- Short Circuit Rating: Equipment must be able to withstand short-circuit currents (fault currents), which can be as high as 40–63 kA depending on the voltage level.

👉 These parameters make sure the system can run smoothly during normal conditions and withstand extreme events without failure.

2. Insulation and Creepage Distance

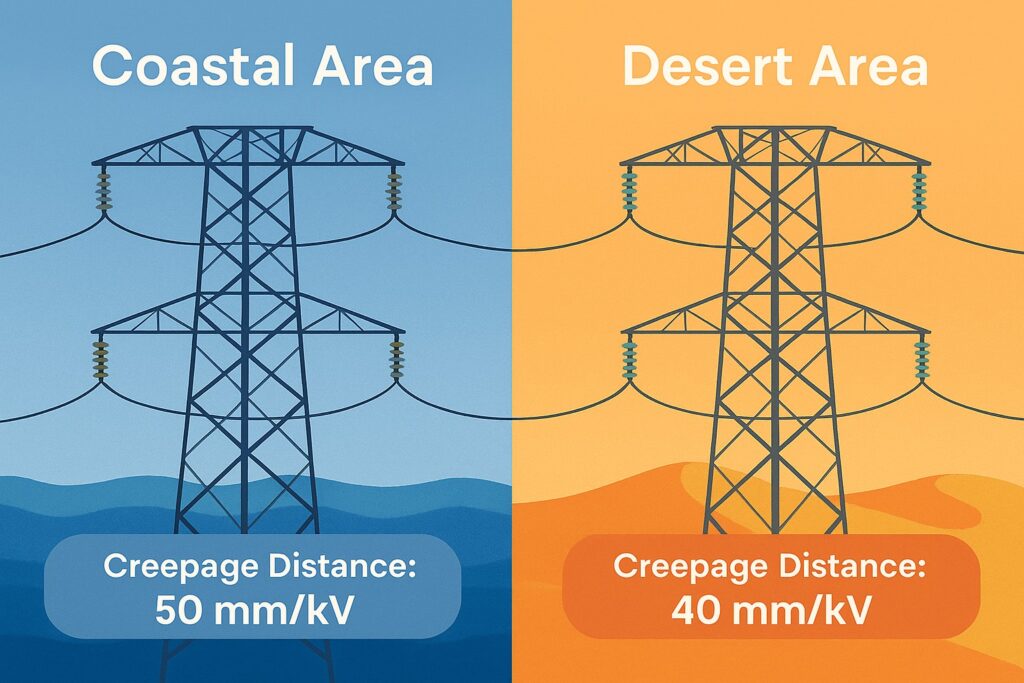

Insulation protects the system against flashovers (sudden breakdown of electricity to ground). The creepage distance (surface distance along the insulator where leakage current flows) is especially important in desert and coastal environments.

- Coastal Areas (humid, salty, and polluted): Require at least 50 mm per kV creepage distance. Insulators here are often coated with RTV silicone for extra protection.

- Inland Desert Areas (dry but dusty): Require about 40 mm per kV.

- Central/Southern Areas (dry with less pollution): Sometimes as low as 31 mm per kV.

💡 Why it matters: Salt, sand, and dust particles can settle on insulators. Without proper creepage distance, moisture can cause flashovers, leading to outages.

3. Structural Supports

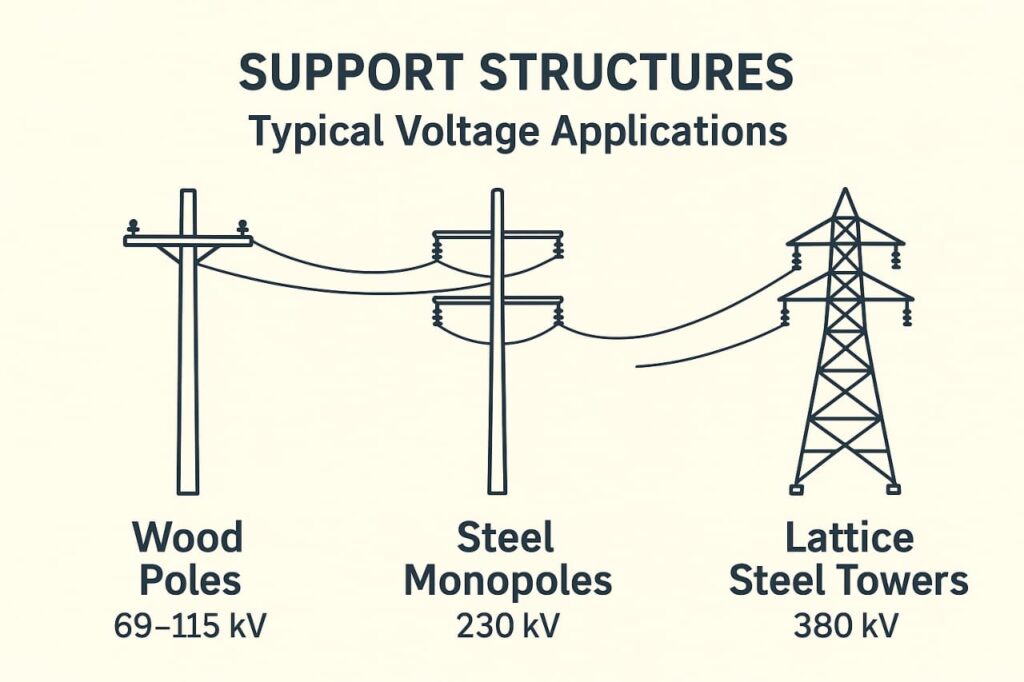

Transmission towers and poles must withstand harsh Middle Eastern weather, including high winds and sandstorms.

- Wood Poles: Used for lower voltage (69–115 kV) in short spans.

- Steel Monopoles: Suitable up to 230 kV, commonly used in urban and constrained areas.

- Lattice Steel Towers: Used for high-voltage lines up to 380 kV, offering durability for long spans.

All structures are designed for wind speeds up to 170 km/h (3-second gusts, 50-year return period). In mountainous passes, wind funneling is studied carefully to prevent line failures.

4. Environmental and Safety Considerations

Public Safety

- Anti-climbing devices are installed about 4 meters above the ground to prevent unauthorized access.

- Warning signs in both Arabic and English are fixed on towers.

- Crash barriers are used near highways to protect structures from vehicle impact.

Pollution and Dust

- The region has low rainfall, meaning insulators are rarely washed naturally.

- Designs consider sandstorms, dust accumulation, and salt spray, which can reduce line performance if not addressed.

Aesthetics and EMI

- Towers are designed to reduce radio noise, audible hum, and electromagnetic interference (EMI) that could affect nearby homes or communication systems.

5. Obstruction Marking and Aviation Safety

Since transmission lines often cross highways, desert routes, and sometimes lie close to airports, they must be clearly visible to aircraft and helicopters.

- Spherical Markers: Bright orange balls installed on overhead ground wires for visibility during the day.

- Warning Lights: Red beacons placed on towers and conductors for night safety.

- Tower Painting: Tall towers near airports are painted in alternating orange and white bands, as per international aviation standards.

💡 This prevents accidents and ensures compliance with aviation safety regulations.

6. Lightning Protection

The Middle East, especially mountainous regions like Abha and Taif, experiences frequent thunderstorms.

- Overhead Ground Wires are installed to shield phase conductors from lightning strikes.

- Shielding Angle:

- For 380 kV lines → ≤20°

- For 69–230 kV lines → ≤30°

- Outage Rate Due to Lightning:

- ≤0.62 outages per 100 km/year for 380 kV and 230 kV lines.

- ≤2 outages per 100 km/year for lower voltages.

👉 In simple terms, this means a 100 km stretch of high-voltage line should face lightning-related trips less than once a year on average.

7. Line Identification and Management

To ensure smooth operation and quick fault location:

- Every tower has number plates showing circuit designation.

- Voltage levels are clearly displayed (e.g., “380,000 Volts”).

- Phase identification plates ensure correct connections during maintenance.

- Aerial identification markers are added for helicopter inspections.

8. Key Takeaways

- Transmission line design in Saudi Arabia and the Middle East is adapted to desert heat, strong winds, corrosion, and lightning.

- Safety is ensured through anti-climbing devices, warning signs, and aviation markers.

- Insulation and creepage distances are tailored to local pollution levels.

- Reliability is achieved through proper wind design, lightning shielding, and strict outage rate limits.

By combining international best practices with region-specific adjustments, engineers create transmission systems that are both robust and efficient for the long term.

ALSO READ: Transmission Line Insulators: Types, Performance, and Design Considerations

FAQs on Overhead Transmission Line Design

1. What is creepage distance in transmission lines?

Creepage distance is the shortest path electricity can travel along the surface of an insulator. In polluted or humid areas like Saudi coastal regions, longer creepage distances prevent flashovers caused by salt and dust deposits.

2. Why are orange balls installed on transmission lines?

The orange balls, called aerial markers, make overhead wires visible to pilots during the day. They are essential near airports, highways, and helicopter flight paths to prevent accidents.

3. How do transmission lines handle lightning strikes?

High-voltage lines use overhead ground wires (also called shield wires) that intercept lightning. These wires safely redirect lightning energy into the ground, protecting the main conductors.

4. Why are towers sometimes painted in orange and white?

This is an aviation safety requirement. Towers near airports or in low-flying aircraft paths are painted in alternating orange and white bands to ensure maximum visibility.

5. What is the acceptable lightning outage rate for transmission lines?

For extra-high voltage lines (380–230 kV), the acceptable outage rate is less than 0.62 per 100 km per year. For lower voltages (69–132 kV), the limit is 2 per 100 km per year. This ensures a reliable power supply even in storm-prone regions.

I’m curious about the follow

1. Do you do live line maintenance?

2. Do you use OPGW as earthwire?

3. Do you use surge arrestors in high lightning ⚡️ areas?

4. What templating temperature do you use for profiling?

5. Which conductor types are you utilising?

6. Do you only use composite insulators or there are where glass is applicable?

7. For dessert conditions which foundations do you use?

8. Which corrosion protections measure are you using besides a thicker galvanic layer on the steel?