Overhead Transmission Lines (OHTLs) are critical assets in any power transmission network. While their design ensures reliability and efficiency, one of the persistent challenges they face is wind-induced vibration. These vibrations, if left unchecked, can lead to fatigue damage, conductor strand failures, and premature aging of fittings.

This is where field vibration measurement becomes vital. By conducting on-site vibration monitoring, engineers can verify the performance of damping systems and ensure that conductors and Optical Ground Wire (OPGW) remain within safe limits.

In this article, we’ll cover the importance, procedures, equipment, and testing setups for field vibration measurement—especially for enthusiasts and professionals working on OHTL design and maintenance.

Why Field Vibration Measurement Matters

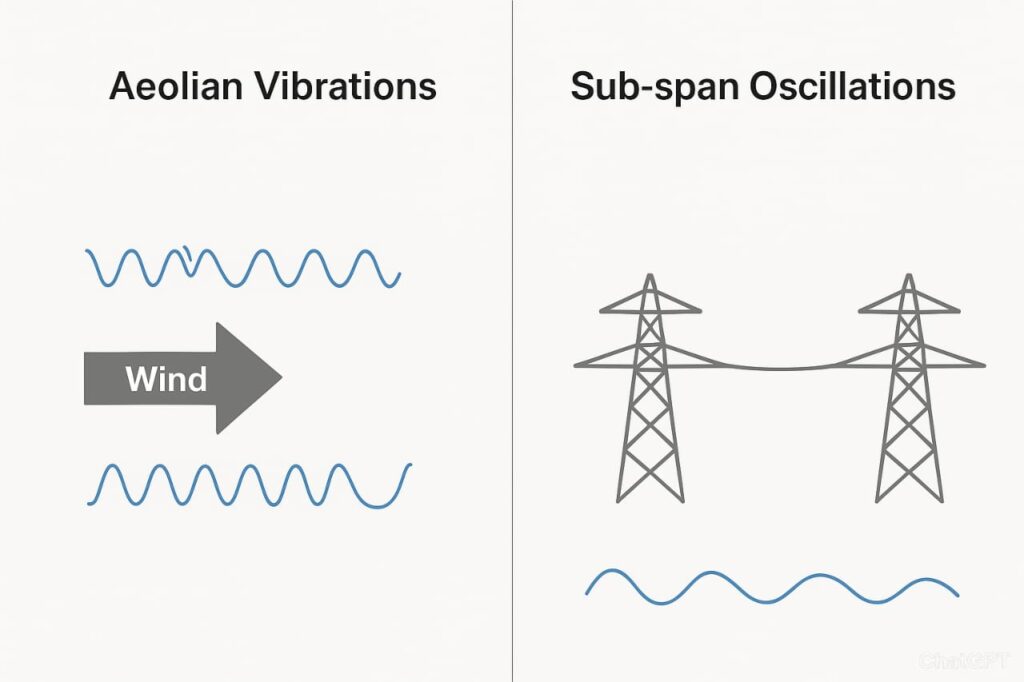

Wind interaction with transmission line conductors generates two primary types of vibrations:

- Aeolian Vibrations – High-frequency, low-amplitude oscillations caused by steady winds (1–7 m/s).

- Sub-Span Oscillations – Larger amplitude movements occurring within bundled conductors, especially in long spans.

If not properly controlled, these vibrations can cause:

- Conductor strand fatigue and breakage.

- Clamp loosening and armor rod wear.

- Spacer damper performance issues.

- Reduced lifespan of OPGW and accessories.

Therefore, measuring these vibrations in the field ensures that damping systems like Stockbridge dampers and spacer dampers are performing effectively.

Field Test Objectives

The purpose of field vibration measurement is to verify that:

- Spacer dampers installed on quad or twin bundle conductors keep Aeolian vibrations within the limit of 200 microstrains (≤ 6.9 MPa stress).

- Stockbridge dampers on OPGW limit vibrations to 150 microstrains (≤ 5.2 MPa stress).

- Sub-span oscillations are restricted to a maximum amplitude of 150 mm peak-to-peak under wind speeds below 18 m/s.

These thresholds follow IEEE Std. 1368 and SEC specifications for vibration performance.

Test Locations and Duration

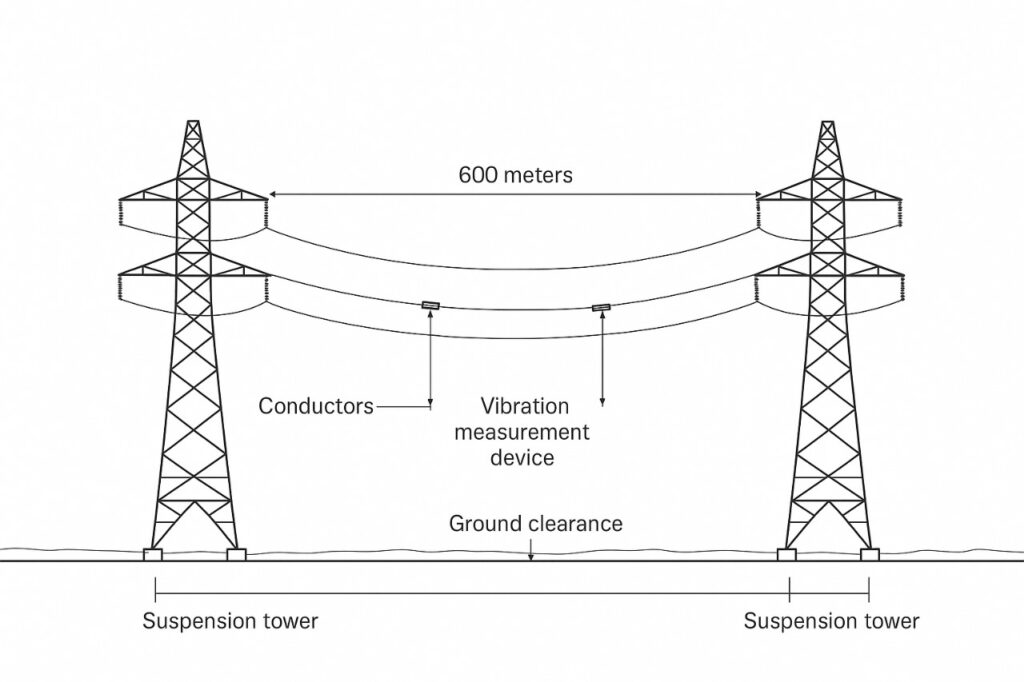

Field vibration measurement is usually performed on:

- Longest spans of the line (typically > 600 m).

- Spans between suspension towers, as they are most exposed to wind-induced oscillations.

- Locations with open terrain and perpendicular wind exposure for worst-case conditions.

Test duration: At least 4 weeks per location, ensuring that different wind conditions are captured.

Equipment Used in Field Vibration Measurement

Two main recorders are commonly deployed:

- VIBREC VR 400 – For Aeolian vibration measurement.

- Measures displacement, frequency (0.2–200 Hz), wind velocity, and bending strain.

- Stores vibration time history and allows FFT analysis.

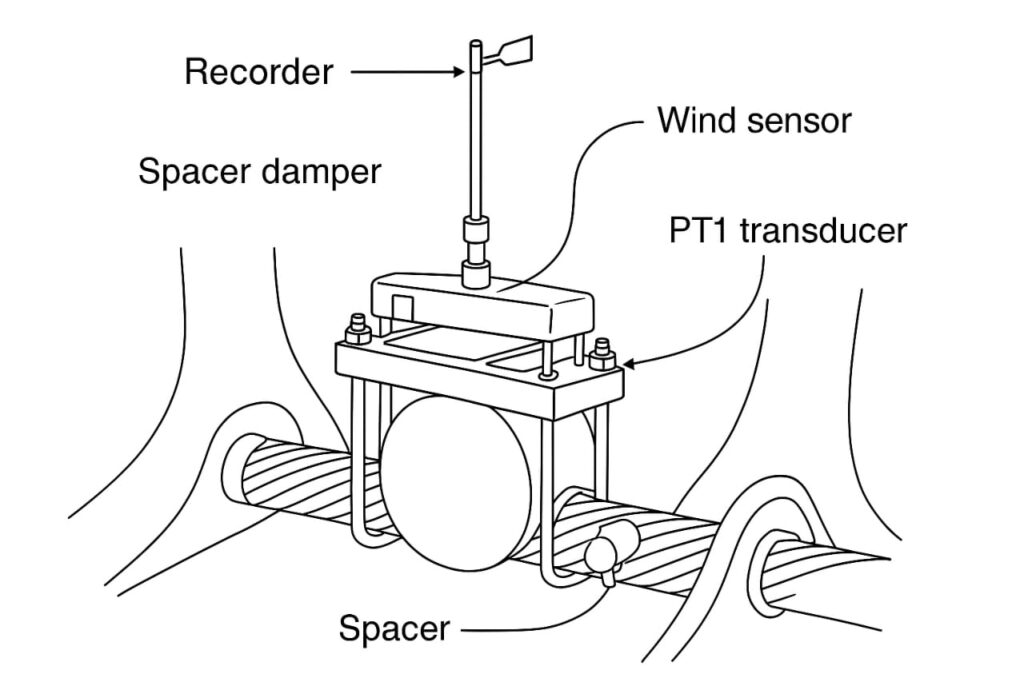

- VIBREC VR 500 PT1 – For sub-span oscillation measurement.

- Equipped with transducers and wind sensors.

- Installed directly on quad/twin bundle spacer dampers.

- Provides graphical analysis of oscillation patterns.

Testing Setup and Installation

1. Aeolian Vibration Measurement

- Recorder is installed on the outer sub-conductor near the suspension clamp.

- For OPGW, the recorder is placed on the armor rod of AGS clamp, with exact distance measured for accuracy.

2. Sub-Span Oscillation Measurement

- Recorder is mounted on the spacer damper frame using U-bolts.

- The PT1 transducer is fixed at ¼ of the sub-span length, ensuring precise detection of oscillation amplitudes.

- A wind sensor is kept vertical for accurate speed monitoring.

Data Analysis and Evaluation

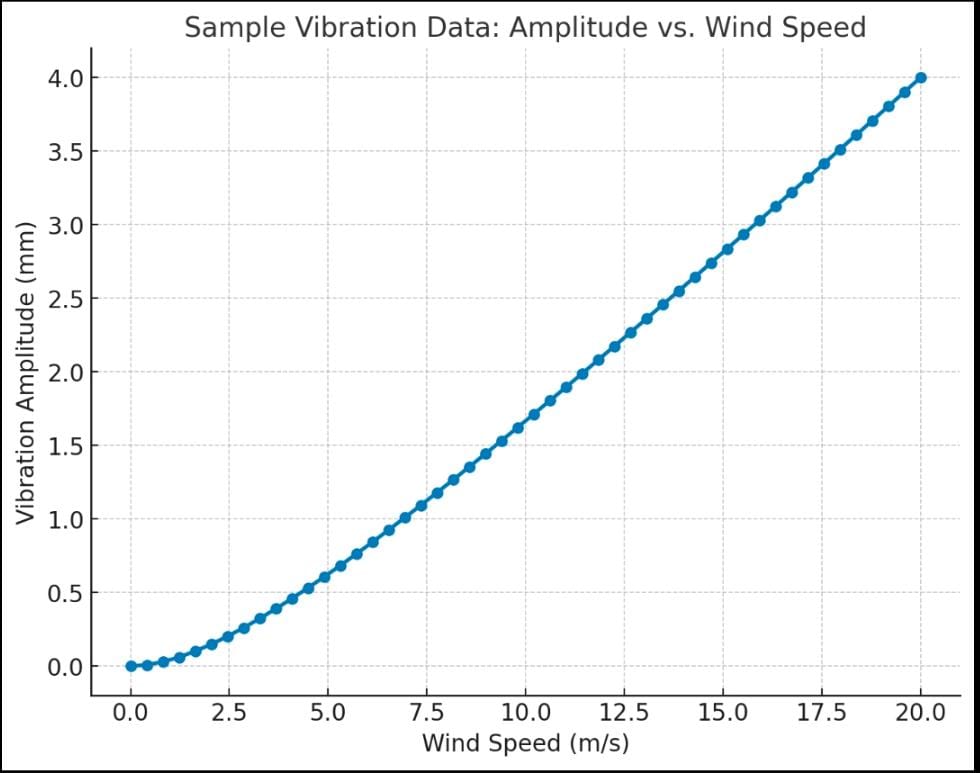

Once data is collected, it is processed using software packages like LIFE 400 and LIFE 500. Engineers analyze:

- Vibration frequency distribution

- Amplitude vs. wind velocity correlation

- Strain levels in conductors/OPGW

- Effectiveness of dampers and spacers

If vibration levels exceed the safe limits, additional damping devices or repositioning of existing dampers may be recommended.

Conclusion

Field vibration measurement is not just a compliance requirement—it’s a proactive maintenance strategy that protects both conductors and network reliability. By using advanced equipment like VIBREC recorders and following IEEE and SEC standards, engineers ensure that OHTL systems can withstand natural wind forces without compromising performance.

For OHTL enthusiasts, understanding this process gives a deeper appreciation of the engineering precision behind transmission line reliability.

Key Takeaway: Regular monitoring, precise installation of recorders, and careful data analysis are the backbone of effective vibration control in overhead transmission lines.

ALSO READ: https://ohtldesign.com/pls-cadd-software-interface-a-step-by-step-guide-for-beginners/

I need field vibration measurement for ohtl 380kv