In Saudi Arabia’s power transmission systems, ensuring network stability under extreme environmental and mechanical stresses is of paramount importance. Transmission lines are exposed to harsh desert climates, strong winds, and high temperatures, which can exert tremendous forces on the line structures. To prevent potential failures, engineers carefully design and implement structures that can safely withstand these forces. One key component in maintaining system reliability is the use of dead-end (anchor) structures along transmission lines.

What Are Dead-End Structures?

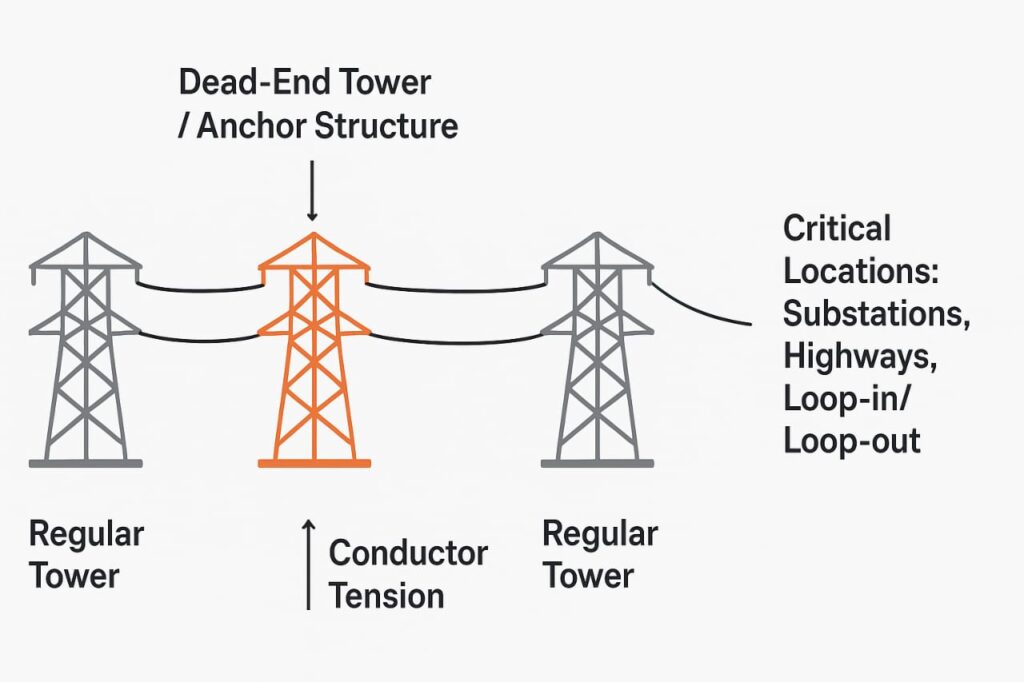

Dead-end structures, also known as anchor towers, are specialized transmission line towers designed to absorb and contain mechanical tension in overhead lines. Unlike regular towers, which primarily support the line, dead-end structures act as mechanical anchors to prevent a single failure from affecting the rest of the network.

These structures are essential in Saudi Arabia, where long stretches of flexible towers are common between main tension towers. Environmental conditions, such as high winds or a snapped conductor, can create strong pulling forces along the line. Without proper dead-ending, these forces can propagate, potentially triggering a cascading failure of multiple towers — an event that can cause widespread power outages.

Purpose of Dead-Ending

The primary goal of dead-ending is to isolate mechanical stresses within a controlled section of the transmission line. This ensures that any abnormal tension or conductor movement does not compromise the structural integrity of neighboring towers.

By strategically placing anchor structures at critical intervals, engineers can:

- Prevent cascading failures: One tower failure does not trigger subsequent failures.

- Control conductor tension: Forces from high winds, broken wires, or thermal expansion are absorbed by anchor towers.

- Maintain grid reliability: Ensures continuous power supply even under extreme conditions.

Dead-ending is particularly important in Saudi Arabia, where transmission lines often span long distances across deserts, wadis, or mountainous terrain.

Spacing of Anchor Structures

The spacing of anchor towers depends on the type of transmission tower and line design. In Saudi Arabia, strict design criteria are followed:

- Wood structures: Every 5 kilometers or less

- Steel structures: Every 12 kilometers or less

Each anchor structure must be capable of withstanding the full tension of all conductors and ground wires from one side, as if the opposite side has completely lost its tension. Proper spacing is crucial to ensure mechanical stability while optimizing the cost and material usage of the transmission line.

Special Span Conditions

Certain spans require additional attention to maintain both mechanical and electrical safety:

- Non-standard spans:

- When the span length is more than 1.7 times or less than half the ruling span, conductors must be dead-ended at both ends and tensioned according to a special ruling span.

- Loop-in/Loop-out (LILO) connections:

- When a new looping tower is added, it should be an anchor or dead-end type to ensure the modification does not impose extra stress on nearby towers.

- Conductor tensions must remain within the original design limits.

- River crossings, wadis, and steep terrains:

- Each case requires careful study to ensure sufficient electrical clearance and prevent conductor clashes due to wind or galloping.

By adhering to these conditions, transmission engineers can maintain structural integrity and prevent costly line interruptions.

ALSO READ: Protective Coating Requirements for OHTL Foundations as per SEC Standards

Locations Requiring Dead-End Structures

Not every tower along a transmission line is a dead-end, but certain locations are considered critical points:

- Near substations or switchyards

- At loop-in/loop-out connections

- When crossing railways or major highways

In Saudi Arabia, major highways are defined as those connecting key cities, airports, seaports, or military zones, which often carry heavy traffic. In some cases, a strong angle tower may serve as a terminal dead-end, provided it is specifically designed for this purpose.

Strategically placing anchor structures at these points ensures both mechanical stability and electrical safety in high-risk locations.

Slack Span Requirements

The slack span — the section between the last tower and the substation gantry — requires special attention. Excessive tension in this short section can cause mechanical stress on the substation structure.

Guidelines include:

- Tension must be less than 5% of the conductor’s ultimate tensile strength, or 30% of normal operating tension, whichever is lower.

- Tension should not exceed the substation gantry’s design limit.

- Typical slack span lengths range from 60 to 100 meters. Any variation requires special approval.

Proper slack span design prevents mechanical failures and ensures the longevity of the transmission line.

Deflection Angle at Substations

At substations or switchyards, the deflection angle — the change in line direction — is limited to 10 degrees. Larger angles are allowed only if the gantry is specially designed and does not compromise:

- Electrical clearance

- Structural integrity

- Side loads on conductors

Maintaining proper deflection angles is essential to ensure safe operation and prevent line sagging or conductor clashing.

Benefits of Dead-Ending in Power Transmission

Dead-ending provides multiple benefits for Saudi Arabia’s electrical grid:

- Enhanced Safety: Isolates high tension forces and prevents tower collapses.

- Improved Reliability: Minimizes cascading failures, ensuring continuous power supply.

- Long-Term Stability: Reduces wear on towers and conductors under extreme environmental conditions.

- Cost-Effectiveness: Prevents costly repairs and unplanned outages by limiting potential failure zones.

- Regulatory Compliance: Meets national and international transmission line design standards.

By incorporating dead-end structures at defined intervals and critical points, transmission engineers can significantly enhance the durability and resilience of Saudi Arabia’s overhead lines.

Summary

Dead-ending is a crucial aspect of Saudi Arabia’s power transmission infrastructure. Anchor structures or dead-end towers play a vital role in controlling mechanical forces, mitigating cascading failures, and ensuring grid stability — even in harsh desert conditions or challenging terrains.

Proper implementation involves:

- Strategic placement of anchor towers

- Adherence to strict spacing guidelines

- Special design considerations for slack spans, substations, and non-standard spans

- Careful analysis of critical locations like highways, railways, and river crossings

These measures ensure the reliability, safety, and longevity of the electrical grid, allowing Saudi Arabia to maintain uninterrupted power supply across the nation.

Disclaimer

This post is for educational and discussion purposes only. All technical details are shared for learning purposes and may vary based on specific project standards, utility requirements, or site conditions.

Sagman