In modern power transmission networks, Optical Ground Wire (OPGW) plays a vital role by combining two critical functions: grounding and high-speed data communication through fiber optic cables. For the reliability and safety of transmission lines, proper OPGW accessories assembly on terminal type towers is essential.

This article provides a detailed overview of the main OPGW accessories and components used in terminal tower installations. Furthermore, it explains how these elements ensure both structural stability and long-term performance.

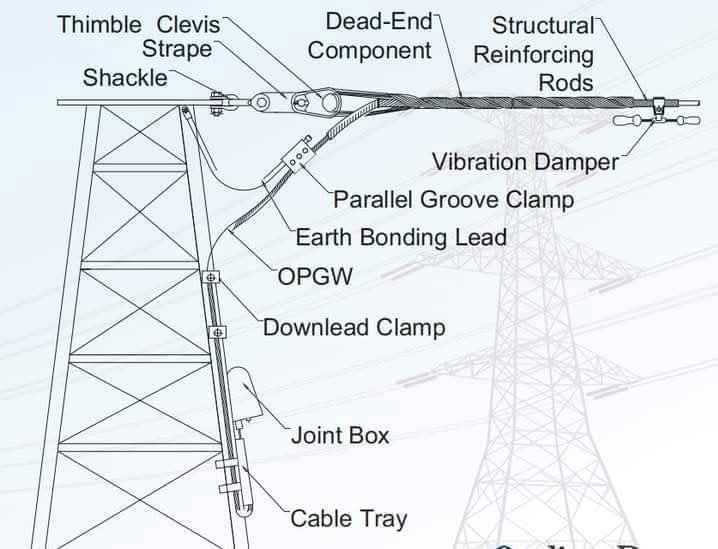

🔹 Key Components of OPGW Accessories Assembly

- Thimble, Clevis, Strap & Shackle

These accessories provide mechanical strength and secure connections between the OPGW cable and the tower structure. - Dead-End Component

Used to terminate the OPGW cable at the tower, ensuring proper tension and anchoring. - Structural Reinforcing Rods

Protect the OPGW cable from mechanical stress and distribute load evenly. - Vibration Damper

Prevents cable fatigue by minimizing aeolian vibration caused by wind. - Parallel Groove Clamp

Provides a strong mechanical and electrical bond between OPGW and the earth bonding lead. - Earth Bonding Lead

Ensures grounding of the OPGW for safe discharge of lightning surges. - Downlead Clamp

Guides and secures the OPGW down the tower, reducing strain on the cable. - Joint Box

Protects and organizes fiber splicing points for seamless optical transmission. - Cable Tray

Provides a secure pathway for fiber optic cables along the tower.

🔹 Importance of Proper OPGW Assembly

OPGW allows utilities to combine communications with grounding, improving operational efficiency. The Prysmian Group, a leading cable manufacturer, explains how modern OPGW designs can withstand harsh environments and deliver long-term reliability.

Reliability: Prevents cable damage and ensures uninterrupted communication.

Safety: Provides effective lightning protection and grounding.

Longevity: Extends the service life of OPGW cables by reducing mechanical stress.

Efficiency: Enhances optical fiber communication within transmission networks.

Also Read: https://ohtldesign.com/tower-testing-in-power-transmission-a-complete-guide/

🔹 Applications of OPGW in Power Systems

High-voltage transmission lines (132kV, 220kV, 400kV, 765kV, and above).

Integration of fiber optic communication networks with electrical grid infrastructure.

Reliable SCADA, protection, and monitoring systems for utility companies.

🔹 Conclusion

The installation of OPGW accessories on terminal towers is a critical task for linemen, engineers, and contractors working in power transmission lines. Proper use of dead-end assemblies, clamps, dampers, and joint boxes is essential because it ensures the long-term performance of both the electrical and communication networks.

For professionals in the lineman industry, understanding each OPGW accessory and its function is key to ensuring safe, efficient, and reliable power system operation.

Pingback: Method of Statement: Vibration Testing in OHTL - ohtldesign.com