When it comes to overhead transmission line (OHTL) design, one of the most critical engineering decisions is the selection of the right type of tower. Transmission towers are the backbone of modern power systems, ensuring reliable and safe delivery of electricity across long distances. Each tower type is designed to withstand different terrain conditions, line deviations, and electrical load requirements.

In this article, we will explore the different types of towers used in overhead transmission lines, their functions, and their suitability for specific conditions.

👉ALSO READ: HVDC overhead transmission line suspension tower and its key components

Why Tower Selection Matters in Transmission Lines

The efficiency, safety, and reliability of a transmission network largely depend on the tower design. Selecting the wrong tower type may lead to:

- High construction costs due to unnecessary material usage

- Mechanical failures under wind or load conditions

- Reduced reliability of the grid

- Increased chances of cascade failures in extreme conditions

That’s why engineers perform tower testing to verify structural strength, design reliability, and compliance with transmission standards before large-scale implementation.

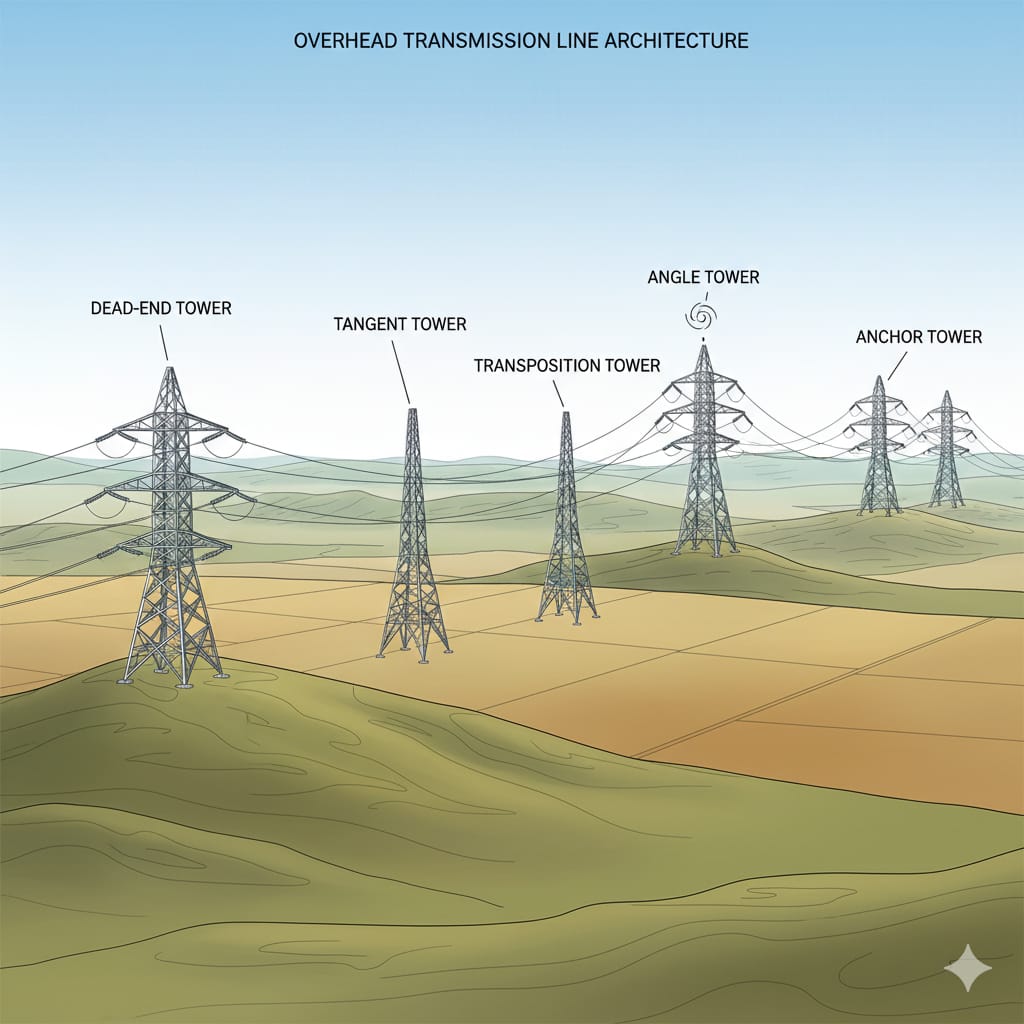

Main Types of Transmission Line Towers

Based on the angle of deviation and voltage levels, transmission towers are broadly classified as follows:

1. Tangent Tower with Suspension Strings

- Deviation angle: 0º–3º (for 69kV to 230kV lines) and 0º–2º (for 380kV lines)

- Purpose: Used where the transmission line runs almost straight.

- Advantage: Economical and lightweight.

2. Small Angle Tower with Tension Strings

- Deviation angle: 2º–10º (69kV to 230kV)

- Also used for: 2º–10º (380kV lines)

- Purpose: Ideal for minor deviations in the line route.

3. Light Angle Tower with Tension Strings

- Deviation angle: 10º–30º (69kV to 230kV)

- Purpose: Supports moderate deviations without compromising line stability.

4. Medium Angle Tower with Tension Strings

- Deviation angle: 30º–45º (69kV to 230kV) and 10º–35º (380kV)

- Purpose: Commonly used in hilly or curved terrains.

5. Large Angle Tower with Tension Strings

- Deviation angle: 45º–60º (69kV to 230kV) and 35º–60º (380kV)

- Purpose: Designed for high-stress deviation points.

6. Heavy Angle Tower with Tension Strings

- Deviation angle: 60º–90º (69kV to 380kV)

- Purpose: Ensures maximum mechanical stability in sharp turns.

7. Anchor Tower

- Deviation angle: 0º–3º (69kV to 380kV lines)

- Special use: Sectionalizing long transmission lines to avoid cascade failures.

- Benefit: Provides additional stability in long stretches of the grid.

8. Dead-End (Terminal) Tower

- Deviation angle: Up to 30º for 69kV–380kV lines

- Purpose: Used at line termination points or where major entry/exit deviations are required.

- Special note: Must withstand maximum load conditions.

9. Transposition Tower

- Deviation angle: 0º–2º (69kV to 380kV lines)

- Purpose: Balances the inductive reactance of conductors by transposing phases along the line.

Key Notes on Tower Design

- Deviation Angles & Spans: Angles mentioned are for the design ruling span, but can be optimized depending on clearances and safety factors.

- Wind & Load Conditions: Towers must meet strict clearance, phase spacing, and safety requirements under worst-case conditions.

- Special Designs: For sites requiring longer spans, custom towers are designed with optimized conductor spacing.

Conclusion:

The types of towers in overhead transmission lines vary based on voltage, angle of deviation, and terrain conditions. From tangent towers for straight routes to heavy angle towers for sharp deviations, each design ensures structural integrity and safe power transmission.

Moreover, modern utilities emphasize tower testing to validate the durability and reliability of each tower type before deployment, making sure that the power grid remains stable under real-world stresses.

By understanding the role of each tower type, engineers and utility planners can ensure cost-effective, reliable, and future-ready power transmission networks.

✅ If you’re interested in learning more about testing methods and structural validation, check out our detailed guide on Tower Testing.

What a summarized offer your articles have been! I can’t stop appreciating you, young engineer!

Thank you.

PS: Can you post “Sag-Tension Analysis”? Any idea on “Galloping”. And finally (for now), can you suggest a the latest material (books, manuscripts, etc.) on the Structural Planning, Analysis, Design and Detailing of various types of towers (material – steel, FGC, concrete, etc.; typology – T-, Y-towers)?

Thanks again.

Thanks for your detailed queries. I’ll be posting the Sag–Tension calculation part in a later phase.

For now, just to share briefly:

Galloping refers to large, low-frequency oscillations of iced/asymmetric conductors under wind. It can cause flashovers, mechanical damage, and high structural stresses. Control methods include spacers, dampers, anti-gallop devices, and design adjustments in galloping-prone areas.

Regarding structural planning, analysis, and design of towers (steel, concrete, composite; T-, Y-type, etc.), the latest references worth checking are:

• ASCE Manual 52 – Design of Steel Transmission Towers

• Design of Electrical Transmission Lines: Structures and Foundations (Kalaga & Yenumula, 2021)

• Recent IEEE/ASCE technical papers on galloping and modern tower materials

I’ll expand with calculations and more detail in the next update.