Introduction

Every transmission tower stands on a foundation, but the stability of that foundation largely depends on the structure pad built around it. A structure pad is more than just a leveled surface — it is a carefully engineered working platform that provides space for tower erection, stringing, and safe access for future maintenance.

In transmission line engineering, the design of the structure pad directly affects the safety, durability, and maintainability of the entire line system. This article explains in detail what a structure pad is, how it is designed, what dimensions to consider, and how to ensure long-term performance — all without going deep into any specific country standards.

What Is a Structure Pad?

A structure pad is a leveled, compacted platform constructed around the base of a transmission tower. It provides:

- Adequate space for erection equipment such as cranes and winches,

- Stability for vehicles and construction operations,

- Safe access for inspection and maintenance, and

- Proper drainage away from the foundation to prevent water accumulation.

In simple terms, it’s the engineered area that allows the tower to “stand and breathe” safely in all weather and terrain conditions.

Why Structure Pads Are Essential

- Foundation Protection – Prevents erosion, waterlogging, and foundation damage.

- Ease of Construction – Offers sufficient working space for cranes, trucks, and lifting equipment.

- Safety During Maintenance – Provides stable access for line crews and maintenance vehicles.

- Improved Drainage – Keeps water away from tower legs and anchor bolts.

- Longevity of the Structure – Reduces the chance of soil settlement or corrosion near the base.

Key Elements of Structure Pad Design

Designing a structure pad involves combining civil engineering, soil mechanics, and safety principles to ensure the pad remains stable in all site conditions. Below are the most important parameters to consider.

1. Earthwork and Material Composition

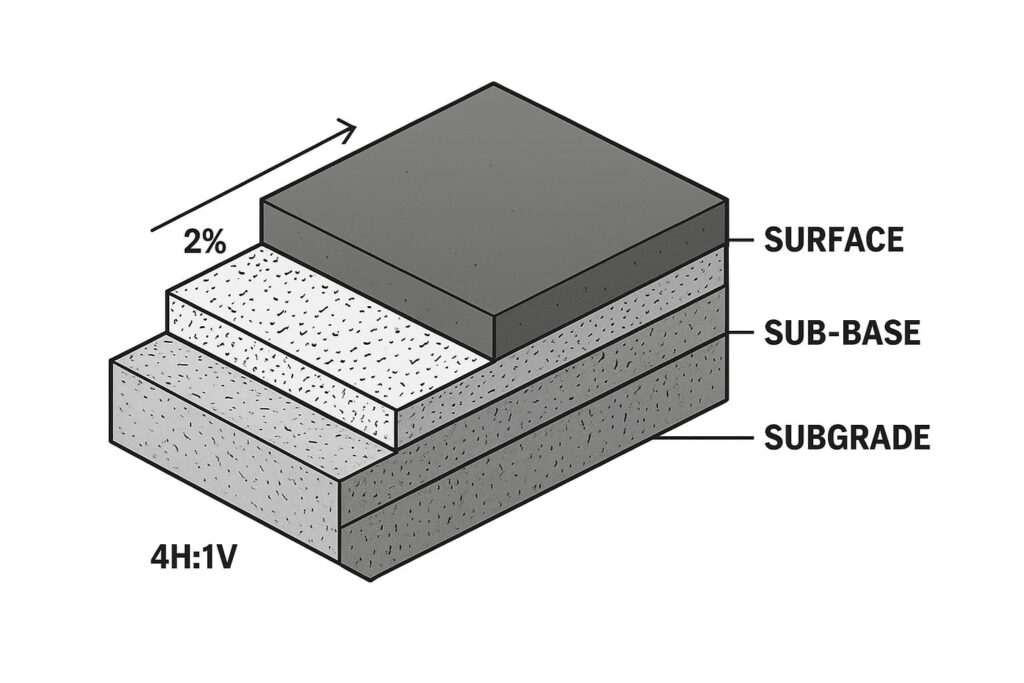

A structure pad typically consists of three compacted layers:

- Subgrade – The original ground, stripped of topsoil and compacted to achieve desired density.

- Sub-base – A layer of select fill material to distribute loads and improve stability.

- Surface (base) layer – The top compacted surface that supports equipment movement.

Each layer must be properly compacted using vibratory rollers, and the material should be free of organic matter, large stones, or debris. Good quality granular soil or crushed rock is preferred for longevity.

For durable performance, the compacted soil layers should generally achieve a California Bearing Ratio (CBR) of around 15% for subgrade and 50% or higher for surface and sub-base layers.

ALSO READ: What is California Bearing Ratio (CBR) in OHTL Foundation Design?

2. Minimum Edge Clearance

The edge of the structure pad should be at least 15 meters away from the outermost foundation point or guy anchor.

This provides enough room for vehicles and construction machinery to operate without disturbing the tower foundation.

3. Side Slopes and Stability

To prevent slope failure and erosion, side slopes should generally not be steeper than 4 horizontal to 1 vertical (4H:1V).

Flatter slopes are always better — they provide more working space, improve safety, and minimize soil erosion.

In hilly terrain, retaining walls or rock protection may be required for additional stability.

4. Grading and Drainage

Proper drainage is one of the most important features of a structure pad.

The surface should be graded 1.5%–2% away from the tower foundation, ensuring that rainwater or wash water flows outwards, not towards the tower legs.

Without proper drainage, standing water can cause corrosion of tower steel, foundation deterioration, and soil instability.

5. Elevation of the Foundation

The top of the tower footing is typically kept around 450 mm higher than the finished surface of the structure pad.

This difference prevents surface water from reaching anchor bolts or stub angles, protecting the tower against long-term corrosion.

6. Structure Pads in Wet or Flooded Areas

In low-lying or water-logged areas, the pad level should be raised at least 1.5 meters above the surrounding ground.

This fill height ensures that the foundation remains dry even during heavy rainfall or flooding.

The fill material should have low plasticity and high bearing capacity — often a blend of compacted sand and gravel.

7. Access and Finger Roads

Structure pads are usually connected to main access roads through smaller approach routes known as finger roads.

These roads allow cranes, trucks, and line stringing equipment to reach each tower location.

Finger roads should be compacted, well-drained, and designed for the same traffic loads as the main access road.

How to Decide the Dimension of a Structure Pad

The most practical way to determine the dimension of a structure pad is to consider tower geometry and construction clearance requirements.

The below provides a simple and effective approach:

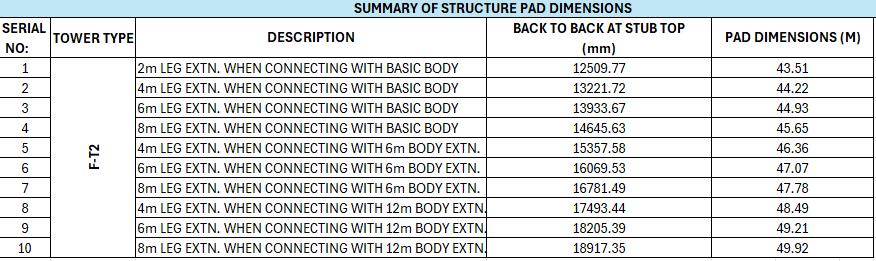

Structure Pad Dimension = (Back-to-Back at Stub Top from Stub Setting Template Drawing in mm) + 15000 mm + Additional Allowance

Where:

- Back-to-Back at Stub Top → distance between opposite legs of the tower, taken from the tower template drawing.

- 15000 mm → a constant buffer area for working space, vehicle movement, and safety margin.

- Additional Allowance → depends on tower type:

- +1000 mm for Suspension Towers

- +1500 mm for Dead-End or Angle Towers

Example Calculation:

If the tower (4m LEG EXTN. WHEN CONNECTING WITH 6m BODY EXTN) back-to-back dimension at stub top is 15357.58 mm, then:

- For a Suspension Tower → 15357.58 + 15,000 + 1,000+15000 = 46357.58 mm (46.36 m)

- For a Dead-End Tower → 15357.58+ 15,000 + 1,500 +15000= 46857.58 mm (46.86 m)

This approach ensures adequate working space for cranes, gin poles, or lifting equipment during erection, as well as safe clearance during maintenance.

The table below shows the real-time pad dimensions for the suspension tower type.

Erosion and Slope Protection Methods

Protecting the structure pad from erosion is essential, especially in desert or flood-prone areas. Common methods include:

- Asphalt or Soil Stabilization Sprays – Applying slow-setting emulsified asphalt or other soil binders to reduce sand drift and surface erosion.

- Rip-Rap Stone Protection – Placing crushed rock or stone (about 300 mm thick) on slopes to prevent washout during rain.

- Concrete Barriers or Lining – For areas with water flow or steep slopes, concrete curbs or retaining structures help maintain stability.

- Contour Trenches – In hilly regions, contour trenches reduce runoff speed and control erosion.

Regular maintenance of these protection systems ensures that the structure pad remains intact for decades.

Best Construction Practices

- Conduct Soil Investigation:

Identify soil type, bearing capacity, and groundwater level before starting construction. - Use Quality Fill Materials:

Avoid organic or expansive soils. Use crushed stone, gravel, or well-graded sand for fill layers. - Maintain Proper Compaction:

Each layer should be compacted to its target density using mechanical rollers or plate compactors. - Control Drainage:

Always grade the pad surface away from the tower foundation to avoid water pooling. - Inspect Regularly:

Periodic inspections after rain or storms help detect early signs of erosion or settlement. - Ensure Safe Accessibility:

Maintain clear routes for future maintenance vehicles and line crew access.

FAQs on Structure Pad Design

Q1. What is the primary purpose of a structure pad?

The structure pad provides a safe, stable, and well-drained platform for tower erection, line stringing, and maintenance activities.

Q2. How thick should the pad layers be?

Typically, each layer (subgrade, sub-base, and surface) ranges from 150–300 mm after compaction, depending on soil strength and design load.

Q3. What slope should the pad have for drainage?

A slope of 1.5% to 2% away from the tower foundation is ideal to ensure quick water runoff.

Q4. Why is pad elevation important in flood-prone areas?

Raising the pad above surrounding ground prevents water accumulation and protects the tower foundation from softening or corrosion.

Q5. Can the same pad dimension be used for all tower types?

No. Pad dimensions vary with tower geometry. Suspension, angle, and dead-end towers each require specific clearances due to different load and equipment requirements.

Q6. How is the structure pad maintained after construction?

Maintenance includes periodic grading, erosion control, inspection of drainage paths, and compaction if needed.

Q7. What happens if a pad isn’t properly designed?

Poorly designed pads can lead to foundation settlement, restricted maintenance access, or even tower instability during storms.

Conclusion

A structure pad is not just an area of leveled ground — it is a key safety and performance element in every transmission line project.

By designing it with the right dimensions, compaction, slope, and drainage, engineers can ensure that towers remain stable and accessible throughout their service life.

Proper structure pad design reduces maintenance costs, prevents erosion, and enhances the overall reliability of the power transmission network.

Disclaimer:

This article provides general guidance on structure pad design for educational and reference purposes. The approach described is commonly practiced in the Middle East, including Saudi Arabia, but exact design parameters should always comply with the project’s governing standards and geotechnical recommendations.