Cranes are essential pieces of lifting equipment in the construction industry, enabling contractors to handle heavy materials, assemble massive structures, and complete complex infrastructure projects efficiently. Among the broad spectrum of crane types available today, telescopic cranes and crawler cranes are two of the most frequently used due to their reliability, versatility, and performance across a wide range of site conditions.

Although both cranes are designed for lifting operations, their engineering principles, operational capabilities, and optimal applications differ significantly. Understanding these differences is crucial for project planners, engineers, and construction managers responsible for selecting the right crane for specific job-site conditions.

This comprehensive guide provides an in-depth technical comparison of telescopic and crawler cranes, focusing on design characteristics, lifting performance, stability, mobility, applications, and overall suitability for different project requirements.

Understanding the Basics of Crane Selection

Crane selection is influenced by multiple factors, including:

- Load weight and radius

- Ground conditions and terrain

- Space availability for setup and operation

- Accessibility and transportation logistics

- Operational efficiency and cost considerations

- Required lifting height and boom configuration

Both telescopic and crawler cranes offer unique advantages suited to specific scenarios. The following sections break down the engineering and operational characteristics of each crane type to help guide informed decision-making.

Crawler Crane: Design, Performance, and Applications

1. Design Characteristics

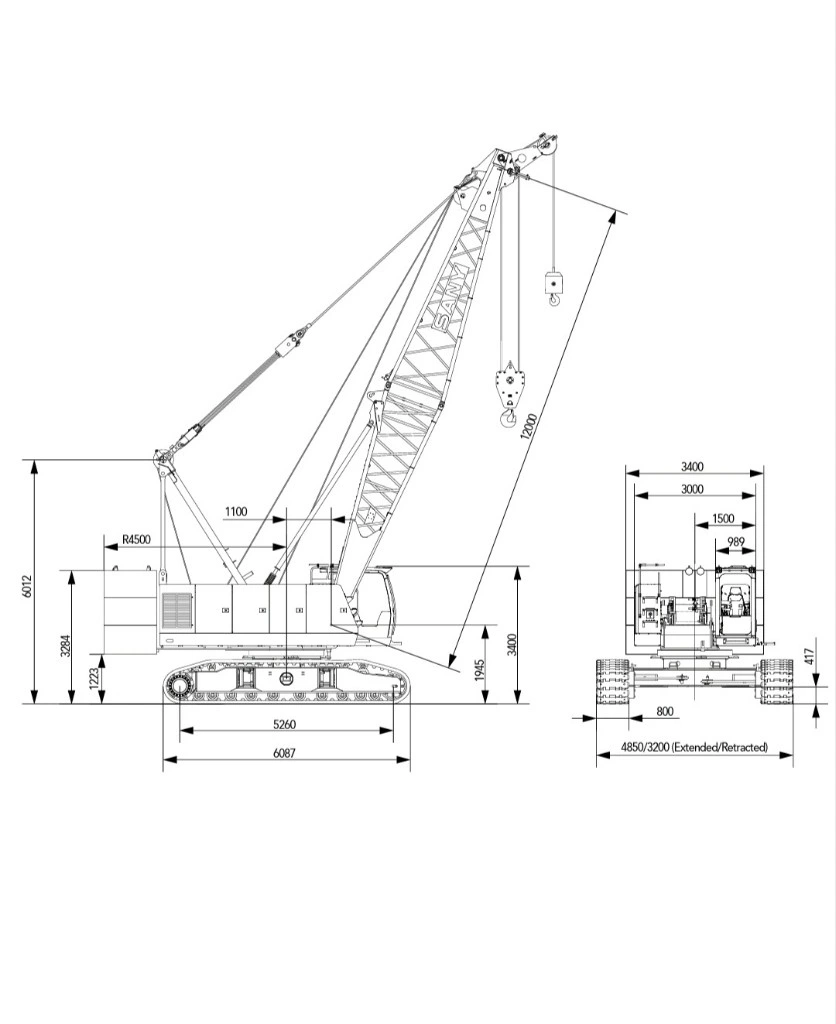

Crawler cranes are built on tracked undercarriages that provide exceptional ground contact and even weight distribution. The tracks allow the crane to maneuver over uneven, soft, or sandy surfaces where wheeled cranes would be impractical or unsafe.

One of the defining features of crawler cranes is their lattice boom, constructed from modular steel sections. This design offers:

- High structural strength

- Lower self-weight compared to telescopic booms

- Customizable boom configurations with additional jibs or attachments

Because of the modular nature of the boom, crawler cranes can be tailored to meet the lifting height and radius requirements of large and complex projects.

2. Lifting Mechanism and Performance

Lattice booms used on crawler cranes are engineered to minimize deflection under extremely heavy loads. Their triangular truss structure provides excellent rigidity, allowing crawler cranes to handle some of the heaviest lifting tasks in the construction industry.

Typical lifting capacities range from several hundred tons, and specialized super-heavy crawler cranes can exceed 1,000 tons, making them indispensable for:

- Industrial plant installation

- Wind turbine erection

- Bridge construction

- Petrochemical projects

Their ability to lift massive loads safely and efficiently sets crawler cranes apart in heavy civil engineering work.

3. Stability and Ground Performance

Stability is a key advantage of crawler cranes. The wide, tracked undercarriage creates a large footprint that significantly reduces ground pressure, enabling the crane to operate on weak or unstable soils without the need for outriggers.

A unique capability of crawler cranes is that many can travel with a suspended load, which:

- Increases overall project efficiency

- Reduces downtime

- Improves positioning accuracy during lift placement

This is a critical benefit on large industrial and infrastructure sites where lifts may need to be performed at multiple locations.

4. Operational Capabilities and Limitations

Advantages

- Extremely high lifting capacity

- Outstanding stability on soft or uneven ground

- Ability to move with the load

- Highly configurable boom system

Limitations

- Complex transport and assembly requirements

- Limited mobility on paved roads

- Large space needed for setup, boom assembly, and counterweights

Crawler cranes are typically transported to site in multiple truckloads, requiring significant planning for logistics and assembly.

5. Common Applications of Crawler Cranes

Crawler cranes are best suited for:

- Large-scale infrastructure projects

- High-voltage transmission tower erection

- Bridge, tunnel, and highway construction

- Petrochemical and heavy industrial work

- Sites with soft, sandy, or unstable soils

Their unparalleled lifting performance makes them essential for any operation involving exceptionally heavy loads or challenging terrain.

Telescopic Crane vs. Crawler Crane: Analytical Comparison

The following table highlights the key differences between the two crane types:

| Criteria | Telescopic Crane | Crawler Crane |

|---|---|---|

| Boom Type | Hydraulic telescopic boom | Modular lattice boom |

| Stability | Depends on outriggers | Very high due to wide tracks |

| Lifting Capacity | Medium to high | Extremely high |

| Site Mobility | Excellent; road-ready | Limited; but can move with load on site |

| Setup Time | Very short | Long; requires assembly |

| Transportability | Great; single vehicle | Complex; multiple loads |

| Ideal Use | Urban, compact sites | Heavy lifting, weak soil conditions |

This comparison shows that while telescopic cranes excel in mobility and setup speed, crawler cranes dominate when high lifting capacity and ground stability are the priority.

Key Factors When Choosing Between a Telescopic and Crawler Crane

Selecting the right crane type requires evaluating the following:

1. Ground Conditions

- Weak or sandy soils → Choose crawler crane

- Stable ground or urban pavement → Telescopic crane

2. Lifting Capacity and Height

- Heavy industrial lifts over 300 tons → Crawler crane

- Medium-duty lifts for building construction → Telescopic crane

3. Mobility and Site Access

- Need for rapid relocation or road travel → Telescopic crane

- Multi-point lifts within a single large site → Crawler crane

4. Project Duration

- Short-term projects → Telescopic

- Long-term infrastructure work → Crawler

5. Space Availability

- Tight spaces → Telescopic

- Wide open job sites → Crawler

Conclusion

Both telescopic cranes and crawler cranes hold essential roles in modern construction, each delivering distinct operational advantages based on project requirements.

Telescopic cranes stand out for their mobility, quick setup, and flexibility, making them ideal for urban construction, building projects, maintenance work, and short-term lifting operations. Their ability to arrive on site ready to work saves time and reduces logistical complexities.

Crawler cranes, on the other hand, provide unmatched stability and lifting power, especially on soft or unstable terrain. They are the backbone of major infrastructure projects, from power transmission line erection to bridge and industrial plant construction.

Ultimately, choosing the right crane depends on a detailed analysis of load characteristics, site conditions, project logistics, and safety considerations. When properly matched to the task, both crane types deliver exceptional performance, efficiency, and operational safety.