Reliable performance of high-voltage transmission lines depends heavily on the proper selection of insulators. Insulators not only support conductors mechanically but also ensure electrical insulation under harsh weather and environmental conditions. Their design and selection vary depending on whether the line passes through coastal or inland areas, the pollution level, and the operating voltage.

General Types of Insulators

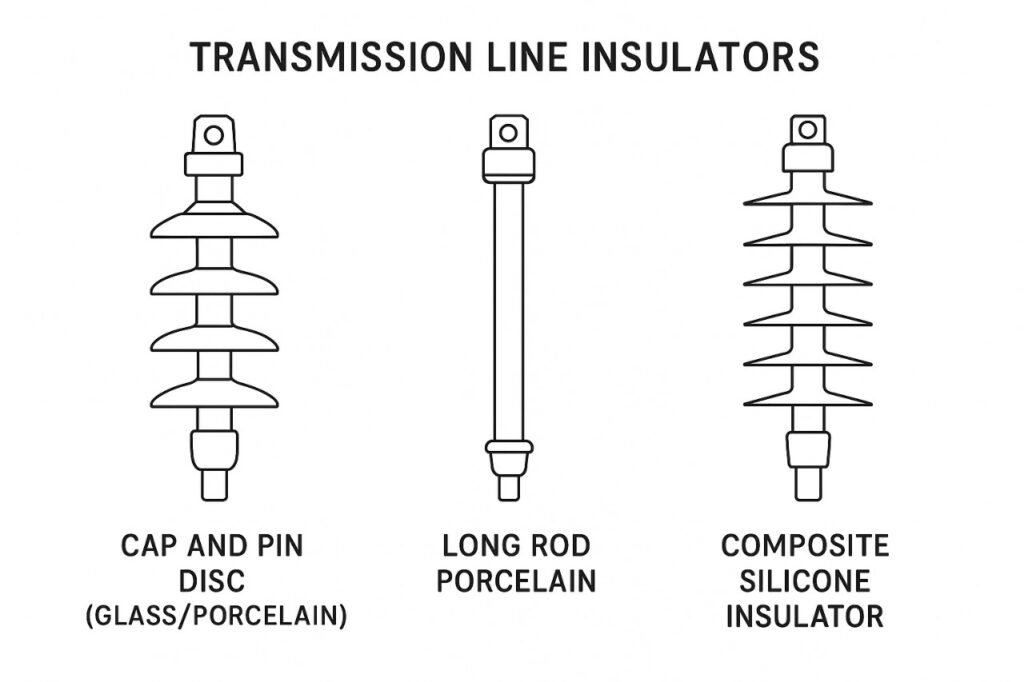

Modern transmission networks commonly use three main types of insulators:

- Cap and pin disc insulators (porcelain or glass, fog or aero form designs)

- Long rod porcelain insulators (aero form)

- Composite insulators (silicone rubber housing with fiberglass core)

Each type has specific applications depending on the project requirements. For example, glass insulators are generally avoided in regions where vandalism is a concern, as they can be easily damaged.

Another important principle is that transmission lines connecting two different regions must adopt the higher creepage distance requirement to ensure reliability.

ALSO READ: https://ohtldesign.com/pls-cadd-software-interface-a-step-by-step-guide-for-beginners/

Service Performance of Insulators

Field experience has shown that insulator performance depends strongly on environmental conditions:

- Composite insulators have shown cracking and surface deterioration in certain inland and coastal sites after only a few years of service.

- Ceramic insulators with RTV (Room Temperature Vulcanizing) silicone coating have provided better performance in aggressive coastal climates.

- Composite insulators up to 230 kV are generally acceptable in coastal regions, but for extra-high voltage lines in salty, humid environments, coated ceramic insulators are still preferred.

The key takeaway: not all insulator types are suitable for every voltage level or location.

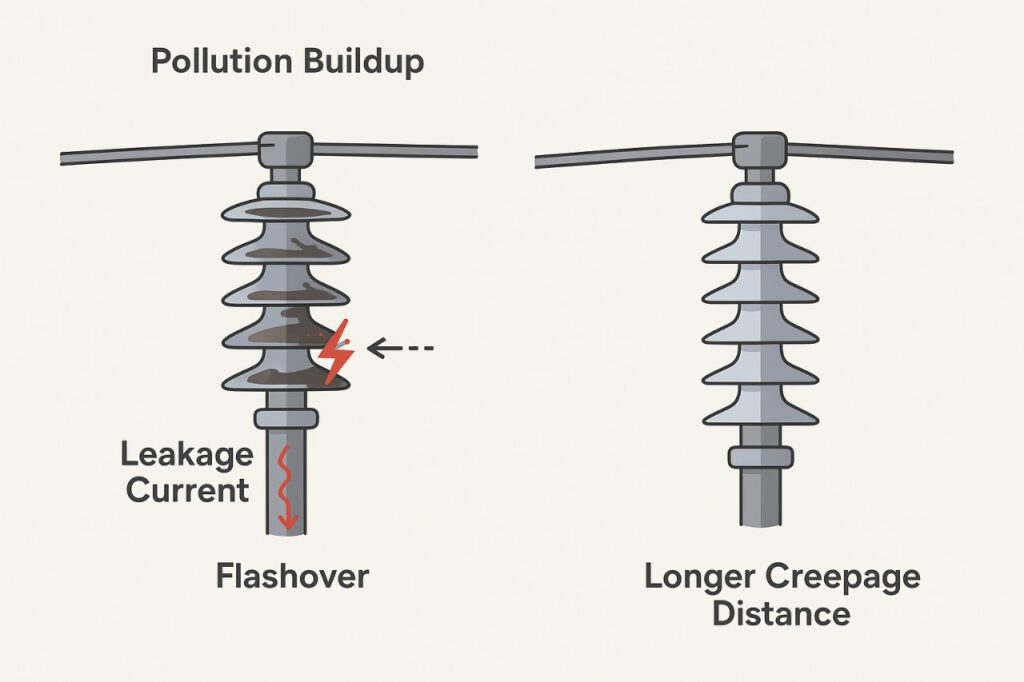

Creepage Distance: A Key Factor in Insulator Design

Creepage distance is the shortest path along the surface of an insulator between two energized parts. It is one of the most critical parameters in transmission line design, especially in polluted, humid, or coastal environments.

Why Creepage Distance Matters

When dust, salt, or industrial pollution deposits on the surface of insulators, it forms a conductive layer. If the creepage distance is too short, leakage current flows easily across the surface, leading to flashovers and outages. A longer creepage distance provides a safer path, reducing the risk of power interruptions.

Recommended Creepage Distances

- Coastal Areas:

- Ceramic (porcelain or glass) → 50 mm/kV

- Additional RTV coating recommended within 50 km of the sea coast.

- Inland Areas:

- Ceramic (porcelain or glass) → 40 mm/kV

- Certain central/southern regions → 31 mm/kV

- Composite Insulators in Coastal Areas:

- Minimum 40 mm/kV, but require special corona ring designs to avoid surface deterioration.

Example:

- A 132 kV line in a coastal area → 132 × 50 = 6,600 mm creepage distance required.

- The same line in an inland central area → 132 × 31 = 4,092 mm creepage distance required.

This difference shows why location-specific insulator design is essential.

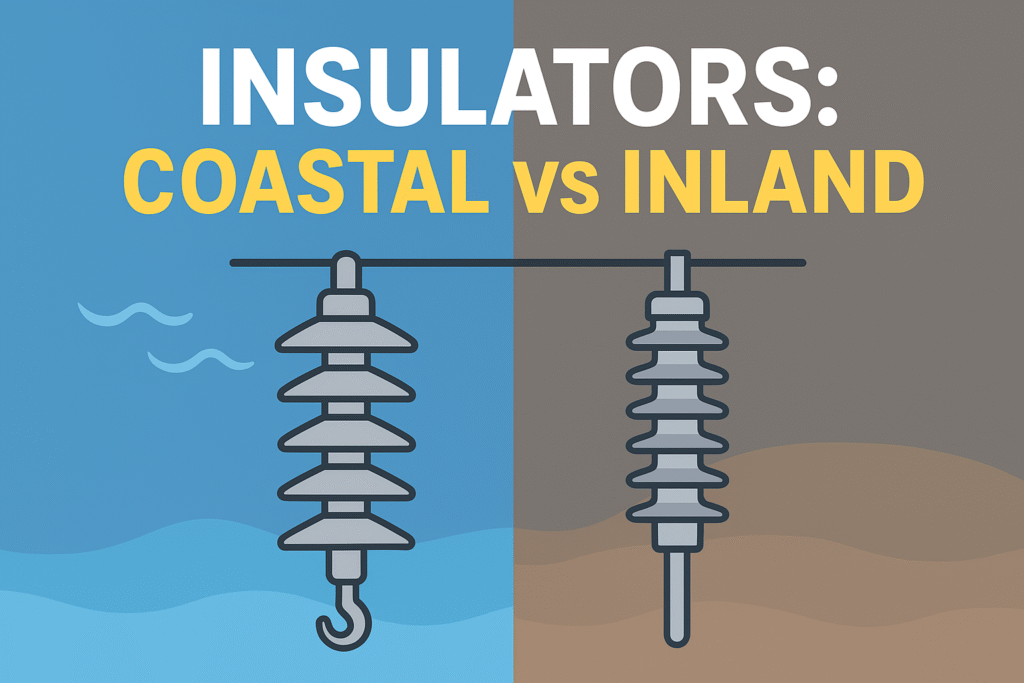

Insulators for Coastal Transmission Lines

Coastal regions are especially harsh due to salt-laden winds, high humidity, and corrosive conditions. Here, insulator design must prioritize both mechanical strength and electrical creepage distance.

- Suspension and tension strings typically require a higher number of insulator units, regardless of whether individual units offer extra creepage.

- Long rod insulators in coastal areas often require creepage distances of several thousand millimeters, especially for high-voltage lines (e.g., 230 kV and 380 kV).

This ensures long-term reliability and minimizes flashover risks.

Insulators for Inland Transmission Lines

Inland areas usually face less contamination, but design requirements still ensure high reliability.

- Aero-form porcelain or glass insulators and long rod porcelain insulators are commonly used.

- Creepage distance standards are lower than coastal areas, but the number of units in each string is still strictly defined by voltage level.

- For upgrades or replacements, engineers must always confirm that phase-to-structure and phase-to-ground clearances remain within safe limits.

Final Thoughts

The choice of transmission line insulators is never one-size-fits-all. Engineers must consider:

- Environmental severity (coastal vs. inland)

- Voltage level of the line

- Long-term performance history of insulator types

- Maintenance and replacement challenges

By carefully selecting insulators with the right type, coating, and creepage distance, transmission lines can operate safely and efficiently in even the harshest environments.

Pingback: Basic Design Requirements for Overhead Transmission Lines in Saudi Arabia and the Middle East - ohtldesign.com